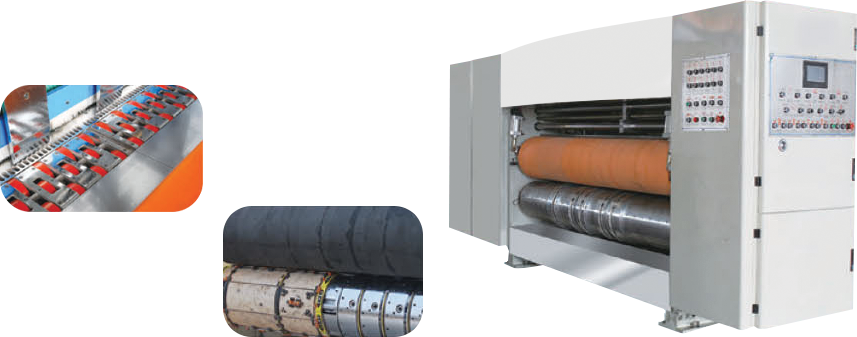

Rotary Die Cutting with Printer adopts chain feeding system and double roller rotary type. It can perform all process of slitting, creasing, corner cutting and hit special whole at one time. It has advantage of high precision, easy to operate, long service life and low cost.

Adopt lead edge feeding system with vacuum adsorption auxiliary feed, (optional equipment kick feeding system)

Speed: 10000 Sheets/Hr, die-cutting precision: ±0.75mm.

Manual adjust former block board and computer control lateral block board, dial indicator.

Leading paper roll have groove glue surface to prevent the crushed card board and increase the accuracy of feeding.

The drum made of high quality steel tube, thickness 30mm, do balance treatment, plated chrome.

Full machine gear made of 45# steel have been quenched treatment, Adopts lock-alx key less and cross-head system connect with shafts finish no gap adjustment.

Driving part uses pull pump to lubricating (motorized phase adjustment type used spray lubricating).

Oil box made of thick iron plate to avoid oil leakage.

Phase adjustment by manual operate with micro-adjustment (or motorized adjust in 360º)

Die Roller (bottom roller) lift-down adopts pneumatic control, manual or automatic operation.

Rubber roller (top roller be wrapped anvil cover from “Maxdura” Brand from Taiwan (or CUE, DAY option), long use life.

Rubber roller (top roller) can move automatically, move range ±40mm.

Rubber roller (top roller) fix overrunning clutch to compensate line speed automatically, and avoid one position cutting.

Equipped with anvil cover repair device, prolong use life.

In the interest of product upgradation/improvement, the

manufacturer reserves the right to change the specifications and features without notice.

The

sizes are standard, any special size required can be supplied on Request.